Why we only use Acrylic Templates

If you are passionate about building instruments such as guitars, then you probably know that the more you build, the more you chase perfection and that's why we have moved to Acrylics as a solution. We have never looked back since using acrylics and if you look at the better builders out there, they are moving to more modern solutions for a better chance of that perfect build.

Quality and Precision

GT has been developing their process around templates and jigs for quite a few years now, originally designing templates for the guitar-making school, and over time they have seen what works and what doesn't.

This is where we see the difference in the type of materials used for jigs. There are pros and cons for all things in life but when quality and precision are the focus, then you can't compromise. We landed on Acrylic, we tried the rest and just kept coming back for so many reasons. Our acrylic templates and designed so precisely that the laser cut is to within 0.5 of a millimetre and this makes a big difference when working on an instrument. You won't find a more precise method. Why would you start with a solution that is knowingly out by a factor of X? That is not to say there isn't room to move when building an instrument such as a guitar, but only in some parts and these areas should be by choice, not because your templates are poorly made.

This is where we see the difference in the type of materials used for jigs. There are pros and cons for all things in life but when quality and precision are the focus, then you can't compromise. We landed on Acrylic, we tried the rest and just kept coming back for so many reasons. Our acrylic templates and designed so precisely that the laser cut is to within 0.5 of a millimetre and this makes a big difference when working on an instrument. You won't find a more precise method. Why would you start with a solution that is knowingly out by a factor of X? That is not to say there isn't room to move when building an instrument such as a guitar, but only in some parts and these areas should be by choice, not because your templates are poorly made.

We intend to outline all the benefits for you but let's start with the most obvious one.

The more accurate the starting position, the less likely the deviation on your instrument build.

That's right, There is nothing more accurate than a laser-cut template, you will be starting with something that is cut to within 0.5 of a millimetre against the file produced. In fact, in the early days of testing, we found the neck joints were so tight when routing a neck and pocket that you didn't need glue when joining them, Well, of course, you do but we had to build an allowance into the templates otherwise it was tough going when adding and removing the neck to the body.

Much like any angle, start with 1° off and it will be 5° off over distance.

" Why start with something that is inferior quality, start with the best for your best chance of a quality build."

Test and Learn

One of the most common materials to make templates is particle board or similar material. We have used these for many years until we saw the light. Typically, these types of boards do not offer the same precision and working solutions that you will find with acrylic, the particle board templates often require workarounds and a range of these workarounds which is not how you should start your build.

This may be acceptable to some people but at GT, we have decided and proven that the better the template the better the outcome and the quicker the build.

Quicker? Yes, we will explain later in this document, for now, we want you to know that our templates are laser cut to within 0.5mm of our designs.

Yes, we will explain later in this document, for now, we want you to know that our templates are laser cut to within 0.5mm of our designs.

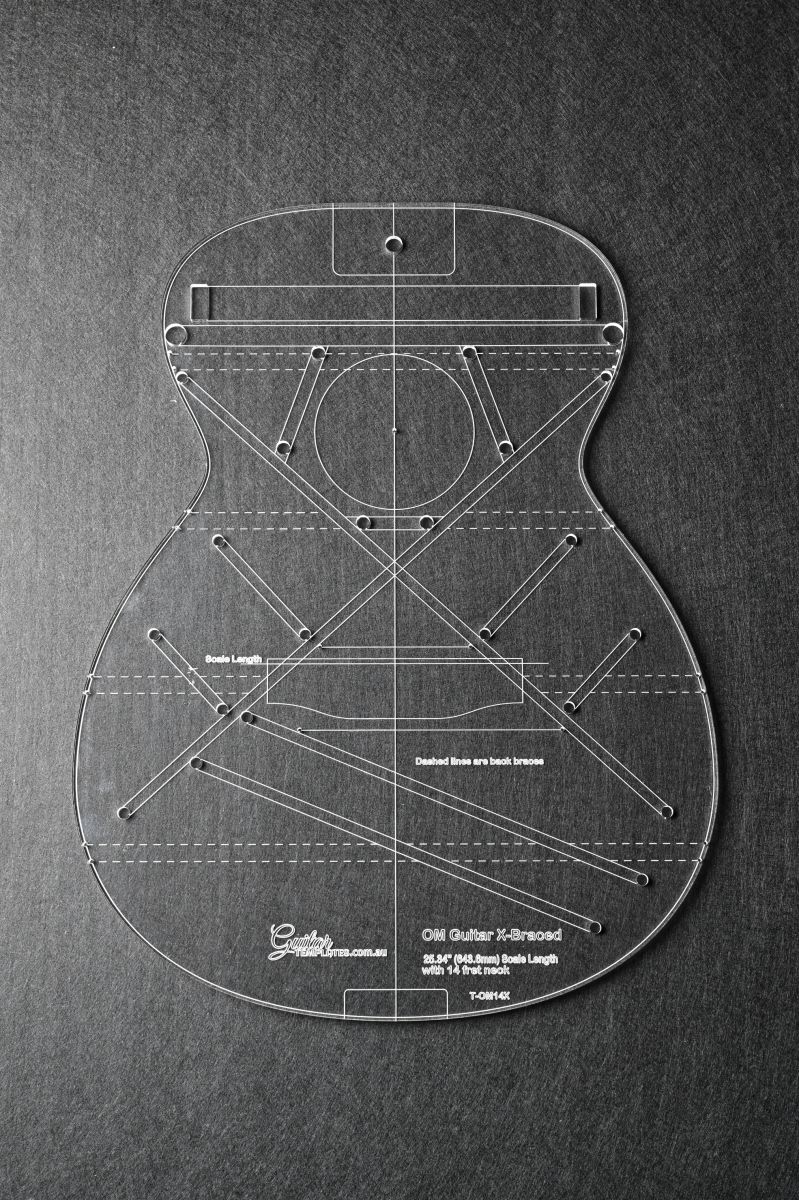

Each template is created from scratch, we do not purchase other people's designs but rather we create our own templates that take into consideration all the information a luthier needs to bring their project to life.

We do this so we can control all the aspects of the build, E.g. We design some guitars that have a fixed neck with the option to create a bolt-on neck solution. These templates use the same base setup and therefore we know any future adaptations will work with your current set.

Over and Over

One of the key reasons GT moved to acrylics years ago was the life span of acrylic templates. We have templates that are over 10 years old and are as precise as the day they were created, yet we found we were replacing templates made from other materials due to inaccuracies, however slight they were. The more accurate a template is the less time you spend fixing things. Pull out your old particle board versions from years ago and they are not the same template you purchased, even worse is if moisture has got to them, warping, and uneven cuts.

Faster Builds

That's right, we can attribute good-quality acrylic templates to faster builds. Here are 3 reasons why.

1. Wear and Tear.

If a template wears out over time due to use, then you may end up with distorted joints and areas that don't quite match up accurately. This means you end up spending more time fixing issues and less time focusing on the things that make the difference between and good and a great guitar.

2. Transparent

These templates are transparent so your lines are all clearly visible and aligning templates over and over is just super easy, accurate and quick.

3. Scores / Marks

All scores/marks are made on the bottom (underneath) of the template, this way you have easy alignment (no shadows or estimates) This means that you are accurate in aligning the template and have fewer issues later.

The smoother the route

The smo other the route the better the build, that's something that we often take for granted these days as we have recreated nearly all our templates in acrylic, yet from time to time we may pull out an old template we haven't yet reproduced and we are quickly reminded how smooth the router runs around an acrylic template versus the older particle board types.

other the route the better the build, that's something that we often take for granted these days as we have recreated nearly all our templates in acrylic, yet from time to time we may pull out an old template we haven't yet reproduced and we are quickly reminded how smooth the router runs around an acrylic template versus the older particle board types.

The same can be said for a sharp pencil, drawing a line against a precision laser-cut template is always smooth and accurate.

Take a headstock template for instance, we notice the older particle board styles end up with rounded corners just from being used, bumped, dropped etc, whereas the precision acrylics templates are still as sharp as the day they were created

Headstocks are rarely cut with a router, usually traced with a pencil and then cut, so you need to start with the most accurate version you can.

Clear Cut Winner

Finally, the number 1 and also the most important reason of all to work with acrylic templates is the clear and accurate working guidelines. Yes, I know we have called this benefit of score marks earlier but that was for speed and now we need to recognise the benefits of transparency. Particle board or timber just can't compete on this level.

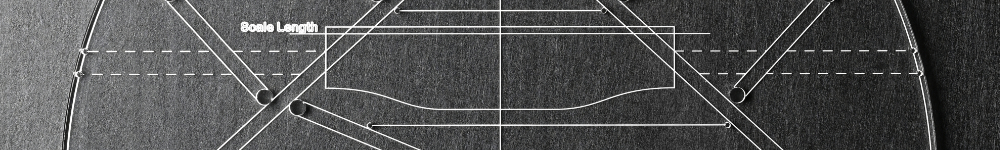

The transparency of acrylics provides the best way to work with guidelines and measurements. All our templates have the key lines, holes and measurements scored on the base of the templates so you can align these marks in the most accurate way.

Precision Markings

That’s right, we can attribute good-quality acrylic templates to faster builds. If a template wears out over time due to use, then you may end up with distorted joints and areas that don't quite match up accurately. This means you end up spending more time fixing issues and less time focusing on the things that make the difference between and good and a great guitar.

A Quick Recap

Slimline Design -Save on Storage Space, we all have no precious space in a workshop and nothing compares to acrylic templates for storage

Super Precise - Accurate to within 0.5 of the original design, the closer the template to the design the more accurate the build will be

Accuracy - Clear and concise markings placed on the base to ensure the lines are easily aligned on your instrument marks

Keeps Shapes - Keeps its original shape over years and years of storage and doesn't warp or swell with moisture

What's the catch?

Well, there is no real catch although they cost a bit more, it is simply the price of the material that adds a bit to the price, however, this is no different with tools, there are some tools that are ok and then there are exceptional tools. they make the difference as acrylic templates will.

People that sell MDF or Particle board templates will say they are better because they sell them, and you may say that we say acrylic is better because we sell them, however, we have tried both and landed where precision and quality matter. We could easily sell particle boards or similar templates but we choose quality over price, we chose accuracy over "good enough" and finally we choose to always seek perfection.

So, if you want precision, smoother edges, clear score marks & lines, and an all-around better starting point then you need to move to acrylic templates, with hundreds and hundreds of templates currently available and more being added every day, you are sure to find what you want but if you can't, simply send us an email to [email protected] and ask for a custom template. We are always happy to help